High Pressure Mass Spectrometry

HPMS – Development

Central to our development of a handheld mass spectrometer is high-pressure mass spectrometry (HPMS). The ability to operate at pressures at or above 1 Torr reduces the vacuum requirements significantly, specifically, the need for a turbo pump. By eliminating the turbo pump and using only a miniature roughing pump to reach operating pressures, unprecedented reductions in the size, weight and power requirements are achieved. We have demonstrated microscale cylindrical ion trap (CIT) operation at pressures above 1 Torr with helium, nitrogen, and air buffer gasses, a factor of 1000 greater pressure than previously reported high pressure MS work.

A tradeoff for working at these higher pressures is a loss of mass resolution due to increased collisions between analyte molecules and buffer gas molecules. Theory suggests that this loss in mass resolution as the pressure increases can be offset by increasing the RF drive frequency. In addition to investigating increasing the RF drive frequency’s effect on mass resolution with pressure, we are also investigating the RF drive frequency’s effect with the size of the cylindrical ion trap. The effect with buffer gas (helium, nitrogen, air) is is another variable being investigated for HPMS work.

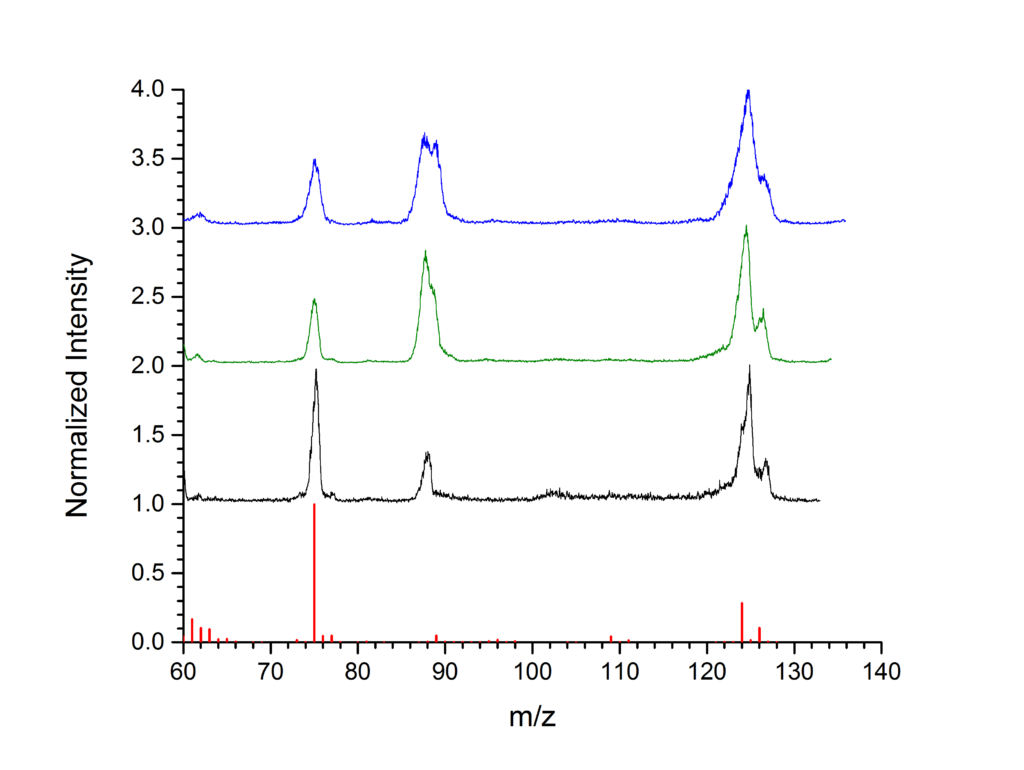

Figure 1 shows some examples of mass spectra of 2-chloro ethyl ethyl sulfide (CEES) taken at increasing operating pressures and varying RF frequencies. The red spectrum shows the NIST standard for peak identification. The black, green, and blue lines show the mass spectra at pressures of 62.7, 538, and 1200 mTorr respectively using a helium buffer gas. As the pressure increases, the peaks broaden however by increasing the RF frequency, this peak broadening effect can be minimized.

Microchip ESI – HPMS Integration

Mass spectrometry is an extremely powerful chemical analysis and detection tool due to it ability to provide molecular information at high sensitivity. The analysis of biochemicals has been revolutionized by electrospray ionization mass spectrometry (ESI-MS) where the liquid sample being electrosprayed is first processed by a chromatographic step. Our group has developed an integrated capillary electrophoresis electrospray ionization microchip (CE-ESI) for the electrophoretic separation of peptides and proteins (see Microchip ESI page). This project looks to address the fundamental question with regards to development of microfabricated technology for performing ESI-MS based chemical analysis; can a microfabricated electrospray device be efficiently coupled to a microscale mass spectrometer? The potential benefits of mating the two systems are:

- Reduction of system volume and weight by 106

- Reduction of power consumption by greater than 103

- Reduction in analysis time by 102

- Enhancement in ion collection efficiency by 10-100 with HPMS operation

- Reduction in maintenance by removal of components such as HPLC pumps and valves

Areas to be investigated include development of ion optics to transfer electrosprayed ions into the trap, constructing a suitable inlet source for efficient coupling of the CE-ESI to the micro-MS instrument and optimizing parameters for maximizing sensitivity.

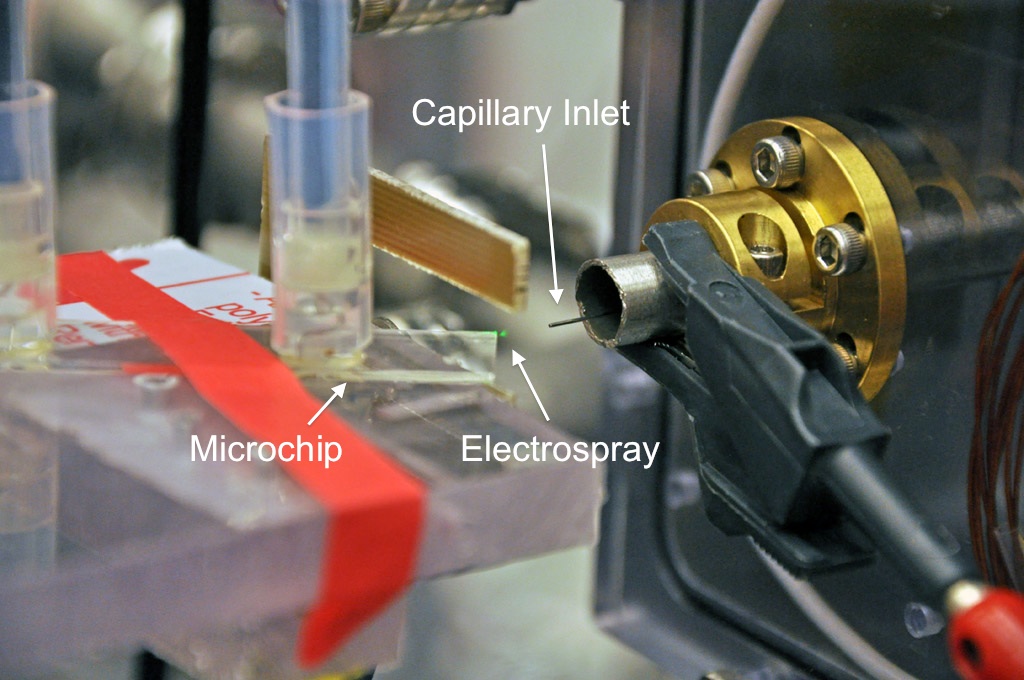

The figure below shows an early iteration of the CE-ESI to MS interface. The green plume in the center of the image shows the electrospray being generated from the edge of the microchip and towards the capillary inlet of the MS instrument.